Lithium-ion batteries have become the backbone of modern energy storage, powering everything from consumer electronics to electric vehicles and large-scale grid systems. As production scales and performance expectations rise, ensuring the safety, consistency, and reliability of each cell has never been more crucial.

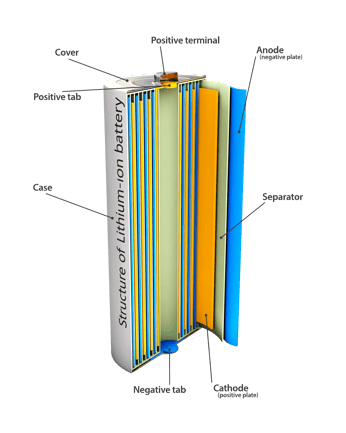

At the core of every lithium-ion battery are four fundamental components, each engineered with precise material properties and manufacturing tolerances:

-

Cathode (Positive Electrode): Typically composed of lithium metal oxides—such as lithium cobalt oxide (LCO) or lithium iron phosphate (LFP)—coated onto aluminium foil.

-

Anode (Negative Electrode): Commonly made of graphite coated onto copper foil.

-

Separator: A thin, porous polyethylene or polypropylene membrane designed to prevent physical contact between electrodes while enabling efficient ion transport.

-

Electrolyte: A lithium-salt-based liquid or gel that facilitates the movement of ions during charge and discharge cycles.

The performance and safety of a lithium-ion cell depend heavily on the quality and uniformity of these components. Even minor deviations, microscopic pinholes, coating non-uniformities, misalignments, or film defects, can impact cycle life, increase internal resistance, or lead to critical failures.

Because of this, inspection and quality control are integral to every stage of battery manufacturing. From raw materials to finished electrodes, manufacturers must validate dimensional accuracy, surface integrity, material distribution, and overall structural consistency.

In this context, four areas stand out for their critical impact on both safety and production yield:

separator production, coating, calendaring and slitting, and electrode slitting.

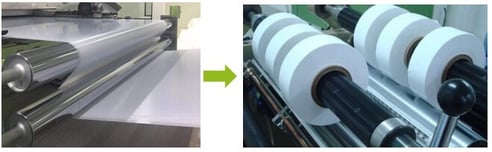

1.Battery Separators Production

Battery separators are a critical safety component, acting as a barrier between the anode and cathode while enabling lithium-ion transport. The production of these membranes involves a highly controlled process to ensure mechanical stability, thermal resistance, and pore uniformity—each essential to cell performance and safety.

Inspection requirements:

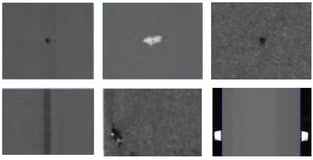

Base Film Defects: Includes pinholes (report immediately), thin or bright spots, black spots, wrinkles, and periodic pattern defects.

• Post-coating appearance defects and classification/grading

Common Defects to Monitor

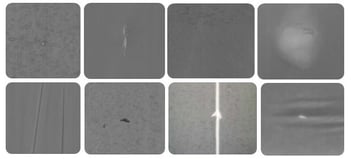

Separator defects can compromise the entire cell. Key issues to inspect include:

• Pinholes: Microscopic holes that can cause internal shorts.

• Thin Spots: Areas with reduced thickness that weaken structural integrity.

• White Spots: Indicators of poor material dispersion or contamination.

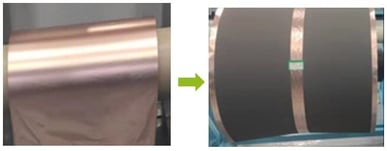

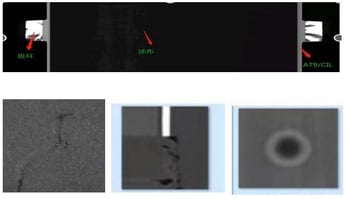

2. Coating

The coating process is key to battery performance, applying active materials onto current collectors with high precision. It requires strict control of thickness, uniformity, and alignment to ensure optimal electrochemical function.

Inspection requirements:

• Dimension measurements include coating width, ceramic layer width, foil area width, alignment accuracy, and virtual edge positioning.

• Inspect the surface for defects and classify or grade them by type, including missing foil, bubbles, pits, drying cracks, wrinkles, scratches, indentations (in both coating and foil areas), particles, oven marks, jagged or uneven ceramic, ceramic mix inconsistencies, dark marks, bulges, and more.

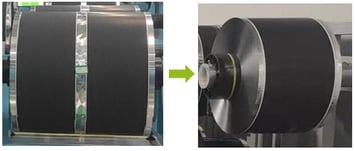

3. Calendaring and slitting

Calendaring and slitting prepare coated electrodes for cell assembly by compressing them to a uniform thickness and then cutting them into precise widths. This improves material density, enhances electrochemical performance, and ensures proper fit and alignment in the final battery cell.

Inspection requirements:

• Dimension measurement of final electrode width after slitting and intermediate foil width after slitting.

• Detect appearance defects and classify them: poor extensibility, foil leakage, air bubbles and pits, drying cracks, wrinkles, scratches, indentations (coating area and foil area), particles, powder loss, etc.

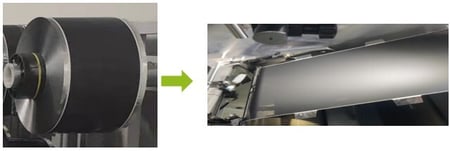

4. Electrode Slitting

Electrode slitting is a critical step in battery manufacturing where large coated electrode rolls are precisely cut into narrower strips to match the required cell dimensions. This process must ensure clean, uniform edges and consistent width to maintain cell performance and prevent defects in later stages.

Inspection requirements:

• Dimension measurement of width of material after slitting, width of intermediate foil material after slitting.

• Detect appearance defects and classify them: poor extensibility, foil leakage, air bubbles and pits, drying cracks, wrinkles, scratches, indentations (coating area and foil area), particles, powder loss, etc.

Camera Solutions and Benefits

In lithium-ion battery manufacturing, processes such as separator inspection, coating inspection, and electrode slitting require a combination of high resolution and high sensitivity to detect critical defects that affect both safety and performance. Defects like pinholes, thin spots, foil wrinkles, or coating misalignments can be microscopic—sometimes just a few tens of microns—yet have major downstream consequences if not caught in time.

JAI’s new SW-8001M-MCL (8k) and SW-16001M-MCL (16k) cameras are a strong match for these challenges. With resolutions capable of achieving sub-10 μm/pixel inspection across wide web widths, they ensure accurate detection of even the smallest surface and dimensional defects without sacrificing throughput. The dual-line TDI architecture increases signal capture during high-speed line scan imaging, helping to reveal subtle issues on low-contrast or dark-coated materials—especially common in graphite and ceramic layers—while keeping exposure times short.

Because many of these materials are light-absorbing, and systems often run at speeds where only microseconds of exposure are possible, the added sensitivity from TDI operation reduces the burden on illumination. This enables more consistent imaging performance with lower light levels, less heat buildup, and reduced energy use, particularly important for inspecting heat-sensitive layers like separators and coated foils.

Together, the SW-8001M-MCL and SW-16001M-MCL offer inspection system builders the flexibility to meet strict resolution and sensitivity demands using fewer cameras, simplifying system design while improving defect detection and yield in high-speed, high-volume battery production environments.