.jpg?width=760&name=iStock-1135140542%20(M).jpg)

The printed circuit board (PCB) industry remains one of the most critical industries in the modern world. With electronics being found in virtually everything around us, the demand for efficient ways to manufacture PCBs – both bare boards and printed circuit board assemblies (PCBAs) – grows each year.

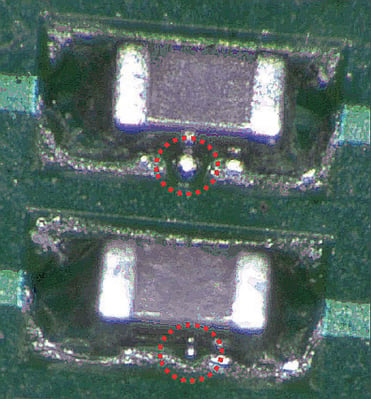

One of the keys to increasing the efficiency of this manufacturing process has been the use of automated optical inspection (AOI) systems to identify issues and defects such as short circuits, missing/misplaced components, component skew, and poor solder quality in the early stages of manufacturing. If not caught early, even small defects can lead to drastic repair costs and field failures later in the lifecycle.

The creation of these AOI systems is a highly competitive business. System builders must choose the right components and algorithms to make sure that their system delivers exceptional value to their target customers. Since these are vision-driven systems, one of the most important component selection decisions is what camera or cameras to use in the system.

In this article, we'll quickly review the four most important camera criteria that system designers need to consider when building their next AOI system.

Criteria #1 - High resolution

As components get smaller and PCBAs get denser, it is critical for AOI systems to be able to clearly "see" tiny details so they can accurately detect problems while minimizing "false positives."

Today, it is likely that even the most basic AOI system contains at least a 5-megapixel camera. Leading systems boast cameras with up to 12-megapixel resolutions to better handle the density and complexity found in modern PCBAs.

Design teams faced with building the next generation of AOI systems would be wise to consider increasing the optical resolution of their system even more. Cameras capable of delivering resolutions of 25-megapixels or more can provide the high levels of detail needed for rule-based AOI systems to better deal with increasing density. And they give AI-based systems more data to use to compare images with their training sets and draw more intelligent conclusions. In addition, with more AOI systems utilizing color information to find and analyze certain types of defects, higher resolutions are essential to overcoming the loss of image detail that takes place during the debayering process.

Criteria #2 – High speed

Despite all of the benefits outlined above, designers can't even consider increasing the camera resolution of an AOI system if it means sacrificing the throughput of the system. Even with the increasing complexity of boards, PCB manufacturers and assemblers know that they must maintain (or increase) their yields, or else risk losing customers to competitors. This makes speed a key issue for the success of an AOI system.

Fortunately, there are camera options available to help AOI system designers find the desired balance between resolution and speed. Even in older AOI systems with 5-megapixel cameras, the expectation was a minimum of 60 to 100 fps. Some 5-megapixel cameras were able to deliver more than 200 fps (see JAI's SP-5000-CXP2 and SP-5000-CXP4 models).

To maintain throughput in next generation systems offering resolutions above 20 megapixels, the challenge of finding a camera with a suitably fast frame rate is harder, but not impossible.

Using advanced CMOS imagers and high-bandwidth interfaces (see next section), new machine vision cameras have been created to not only meet the speed requirements of today's 12-megapixel systems, but also to take these systems to the next-level of resolution.

As a prime example, a camera like JAI's 26-megapixel SP-25000-CXP4A can not only meet the 60-100 fps target set by current 12-megapixel systems, but it can also run at up to 150 fps to provide both higher resolution and higher throughput. Or it can use its frame rate to maintain current throughput while supporting more advanced algorithms that may utilize multiple images per PCBA to provide better defect assessment.

Criteria #3 – Fast interface

As suggested in the previous section, hitting your speed and resolution targets requires two things from your camera: a fast sensor; and an interface that can handle all the image data being generated. Regardless of the resolution of your system, if maximizing throughput is a key competitive requirement, you'll want to look for a camera with a high-capacity interface.

For example, the latest version of the CoaXPress standard interface (v2.0) can now support up to 12.5 Gbps per cable and can be configured with four parallel lanes in a single interface. The resulting 50 Gbps bandwidth provides enough capacity to transfer your 26-megapixel, 8-bit images from your camera to your processor at up to 150 fps.

Not all CoaXPress cameras support these so-called "CXP-12" lane speeds, but even if the camera operates at a more modest 6.25 Gbps per channel (CXP-6), a four-lane interface can give you 25 Gbps to enable your high resolution images to easily meet a 60-100 fps target.

Some AOI systems may place an emphasis on specialized types of defect detection and may not need to over-emphasize throughput to win customers. For these systems, a Camera Link "deca" interface, operating at up to 6.8 Gbps might even be sufficient bandwidth.

Alternatively, a camera with a 10 GigE (Gigabit Ethernet) interface could be considered for these less demanding requirements. This interface can provide 9-10 Gbps of data bandwidth and at the same time eliminate the need for a specialized interface board (frame grabber) in the host PC, provided the PC has a standard NIC supporting 10 GigE speeds.

Criteria #4 – The right shutter method

Maintaining high throughput in an AOI system means capturing images of boards that are moving rapidly through the field of view of the imaging system. There are two types of cameras to consider to best deal with this situation.

First, are cameras with global shutters. These cameras expose the whole image (every pixel) simultaneously. This means they can "freeze" a fast-moving object with a minimum of blur or distortion, as long as they have a fast enough frame rate and exposure setting (shutter speed). This is in contrast to "rolling shutter" cameras. These cameras are attractive to design teams because they typically cost less per megapixel than global shutter cameras. However, they use a staggered, line-by-line exposure method that causes fast-moving objects to appear "skewed," making the images unacceptable for many types of defect detection.

But there is a second option. Some rolling shutter cameras have a mode called "global reset" which enables them to start exposing all lines at the same time, even though they still stagger the end of the exposure on a line-by-line basis. By using a flash to freeze the action during the start of the exposure period, and then blocking light during the rest of the exposure, a rolling shutter camera becomes a possibility for high-speed AOI. But this requires that the rolling shutter camera meets all the previous requirements: high resolution, high frame rate, and high-capacity interface, and it requires that the AOI system can control the ambient lighting in the field of view, such as by "shrouding" the conveyor that is transporting the PCBs through it. Only if all these requirements are met can a rolling shutter camera be considered.

Putting it all together

The creation of AOI systems for PCBs and PCBAs is a large and vibrant business. Properly implemented AOI systems can have a significant impact on the success and profitability of the PCB manufacturers who utilize them in their production process.

To succeed as a supplier of these AOI systems, machine vision builders must make sure that their systems provide excellent results, both in terms of the quality of their defect detection and the overall throughput that they support. By carefully considering the four camera-related factors described here, AOI system builders can maximize the performance of their systems in this highly competitive market.