Thanks to ongoing developments in digital camera and image sensor technologies, as well as faster data transmission interfaces and advanced computer image processing algorithms, automated vision inspection systems continue to grow more sophisticated and efficient.

These technological improvements have given manufacturing companies the possibility to speed up production processes, thereby improving manufacturing efficiency and production yields. At the same time, advances in camera technology have enabled better quality inspection routines across the manufacturing line leading to higher quality of finished products.

The most widely applied imaging technique in machine vision systems is still industrial cameras with color and monochrome CMOS sensors detecting visible light in the electromagnetic range of approximately 400 nm to 700 nm. But in recent years the machine vision industry has seen a growing interest in industrial cameras that are able to detect photons beyond the visible light spectrum, for example cameras with Indium Gallium Arsenide (InGaAs) sensor technology capable of detecting Short Wave Infrared (SWIR) light waves (~1050 nm to ~2500 nm).

This free white paper describes how SWIR

This free white paper describes how SWIR

imaging can improve the efficiency

in food and beverage inspection systems.

Compared to visible light, SWIR light has a different physical behavior when interacting with material. SWIR light can transmit deeper into both organic and non-organic material where the light photons get absorbed when interacting with the molecules in the material. The level of absorption depends on the chemical structure of the material. Water molecules for example have a high absorption level of SWIR light at wavelengths between 1,450-1,500 nm.

This makes SWIR imaging useful in applications such as fruit and vegetable inspection, as early decay and bruises (typically areas with higher water content) show more clearly in the SWIR light spectrum by appearing as areas with higher contrast in the camera images. This enables items with these defects to be more readily identified and removed from the conveyer belt before packaging.

The most widely applied imaging technique in machine vision systems is still industrial cameras with color and monochrome CMOS sensors detecting visible light in the electromagnetic range of approximately 400 nm to 700 nm. But in recent years the machine vision industry has seen a growing interest in industrial cameras that are able to detect photons beyond the visible light spectrum, for example cameras with Indium Gallium Arsenide (InGaAs) sensor technology capable of detecting Short Wave Infrared (SWIR) light waves (~1050 nm to ~2500 nm).

This free white paper describes how SWIR

This free white paper describes how SWIRimaging can improve the efficiency

in food and beverage inspection systems.

Compared to visible light, SWIR light has a different physical behavior when interacting with material. SWIR light can transmit deeper into both organic and non-organic material where the light photons get absorbed when interacting with the molecules in the material. The level of absorption depends on the chemical structure of the material. Water molecules for example have a high absorption level of SWIR light at wavelengths between 1,450-1,500 nm.

This makes SWIR imaging useful in applications such as fruit and vegetable inspection, as early decay and bruises (typically areas with higher water content) show more clearly in the SWIR light spectrum by appearing as areas with higher contrast in the camera images. This enables items with these defects to be more readily identified and removed from the conveyer belt before packaging.

Another application where SWIR imaging shows its strength is in relation to detecting foreign objects. For example, in food processing, items like stones, metal and plastic need to be detected and efficiently removed before further processing. In bulk inspection of fresh vegetable produce, foreign items can be difficult to identify using only color images from visible light, but on the SWIR images they will show up as darker objects compared to the food items and can therefore be identified by the software algorithms and removed by the separation mechanism on the conveyer belt.

As SWIR light also has the ability to “see through” opaque plastic and glass, this technique can also be used for checking contamination in packages and containers and verifying the correct amount of content or fill levels of liquids or powder.

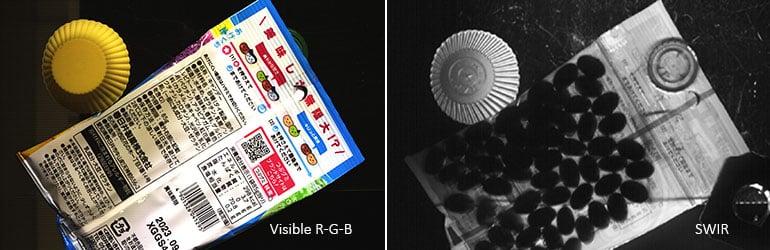

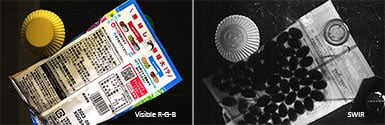

With the new R-G-B-SWIR line scan camera (SW-4010Q-MCL) it´s possible to inspect, for example, the quality and completeness of the outside of a food container and simultaneously look at the content inside.

As SWIR light also has the ability to “see through” opaque plastic and glass, this technique can also be used for checking contamination in packages and containers and verifying the correct amount of content or fill levels of liquids or powder.

With the new R-G-B-SWIR line scan camera (SW-4010Q-MCL) it´s possible to inspect, for example, the quality and completeness of the outside of a food container and simultaneously look at the content inside.

In inspection stations checking the quality of semiconductors, SWIR can help to find defects on the surface and below the surface of silicon wafers as SWIR light can “see” through silicon.

Applications such as textile and wood inspections can use SWIR imaging to check if dyed textile is dry enough for further processing or if cut wood has hidden defects. Other applications include waste sorting of different plastic types, mineral sorting, battery inspection and agriculture/forestry applications.

Even though SWIR cameras can pave the way for added efficiency in the inspection process, many machine vision applications still need cameras looking at normal visible light to check size and shape, as well as analyzing color nuances of objects or checking the color of labels or other printing. So, SWIR imaging can be considered as a good supplement to normal inspection routines with visible light waves. Meanwhile, in many applications both visible and non-visible imaging techniques are needed on the same manufacturing line to fulfill quality inspection requirements.

Traditionally, inspection stations looking at visible light and SWIR or NIR light have been integrated as separate inspection steps along the manufacturing line, with separate cameras, lighting, lensing, and mounting making the set-up task more complex and expensive.

To address this issue, the industrial camera manufacturer JAI has launched new multi-sensor camera technology making it possible to simultaneously take images of visible plus SWIR light with just a single camera.

To address this issue, the industrial camera manufacturer JAI has launched new multi-sensor camera technology making it possible to simultaneously take images of visible plus SWIR light with just a single camera.

JAI’s latest product addition is a color line scan camera in the Sweep+ Series that integrates three CMOS line sensors with a resolution of 4,096 pixels each, plus an additional InGaAs sensor having a resolution of 1,024 pixels in a line.

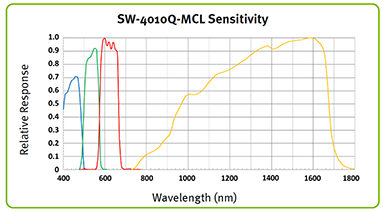

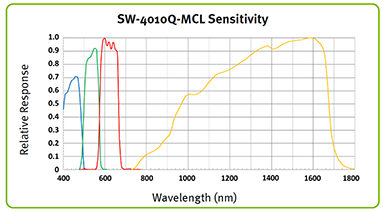

A new multi-sensor line scan camera (SW-4010Q-MCL) from JAI simultaneously captures red, green, and blue visible light via three separate CMOS sensors (400 to 700 nm), plus SWIR light (~800 to ~1700 nm) via a fourth sensor based on InGaAs technology.

Via advanced in-camera prism technology and dichroic filters, the camera splits the incoming light into the four different channels for simultaneous capturing of red, green, and blue visible light on the three CMOS sensors, while the InGaAs sensor catches SWIR light waves.

A new multi-sensor line scan camera (SW-4010Q-MCL) from JAI simultaneously captures red, green, and blue visible light via three separate CMOS sensors (400 to 700 nm), plus SWIR light (~800 to ~1700 nm) via a fourth sensor based on InGaAs technology.

Via advanced in-camera prism technology and dichroic filters, the camera splits the incoming light into the four different channels for simultaneous capturing of red, green, and blue visible light on the three CMOS sensors, while the InGaAs sensor catches SWIR light waves.

With just a single inspection station it is then possible to provide image data for checking very subtle color nuances, while simultaneously providing a better method to locate hidden defects or unwanted objects via the SWIR imaging data.

The chart shows the spectral response for each of the three CMOS sensors (blue, green and red) as well as the InGaAs sensor capturing SWIR light. (The height of the SWIR (yellow) line is not correlated to the RGB lines).

The new line scan camera includes a range of advanced functions such as a built-in color space conversion that can convert the RGB output to specific color spaces like HSI, CIE XYZ, sRGB and Adobe RGB. To improve image brightness and color balance, it is possible to set the exposure time individually for R-G-B and SWIR channels thereby increasing light accumulation time for the different wavebands. Also, analogue, and digital gain can be set individually for the four channels. The maximum line rate for the R-G-B channels when set to 4096-pixel resolution is 20 kHz and for the SWIR channel it´s 39 kHz in 1024-pixel resolution. Base pixel size is 7.5 x 7.5 µm for the R-G-B channels, 25 x 25 µm for the SWIR channel.

To synchronize the Field-of-View (FOV) and the line rate of the R-G-B and SWIR sensors, the camera features a special pixel rescaling function called Xscale. By using the Xscale function to adjust the pixel size of the RGB sensors (in combination with Region-of-Interest settings), the sensor width of the RGB sensors goes from 30.72 mm to 25.6 mm which is the same width as the SWIR sensor. At the same time the R-G-B scan rates increase from 20 kHz to 39 kHz which is equivalent to the SWIR scan rate.

This free white paper describes how SWIR

This free white paper describes how SWIR

imaging can improve the efficiency

in food and beverage inspection systems.

More information about the R-B-G-SWIR line scan camera:

For more information about the Sweep+ SW-4010Q-MCL line scan camera: Please visit the product page

The new line scan camera includes a range of advanced functions such as a built-in color space conversion that can convert the RGB output to specific color spaces like HSI, CIE XYZ, sRGB and Adobe RGB. To improve image brightness and color balance, it is possible to set the exposure time individually for R-G-B and SWIR channels thereby increasing light accumulation time for the different wavebands. Also, analogue, and digital gain can be set individually for the four channels. The maximum line rate for the R-G-B channels when set to 4096-pixel resolution is 20 kHz and for the SWIR channel it´s 39 kHz in 1024-pixel resolution. Base pixel size is 7.5 x 7.5 µm for the R-G-B channels, 25 x 25 µm for the SWIR channel.

To synchronize the Field-of-View (FOV) and the line rate of the R-G-B and SWIR sensors, the camera features a special pixel rescaling function called Xscale. By using the Xscale function to adjust the pixel size of the RGB sensors (in combination with Region-of-Interest settings), the sensor width of the RGB sensors goes from 30.72 mm to 25.6 mm which is the same width as the SWIR sensor. At the same time the R-G-B scan rates increase from 20 kHz to 39 kHz which is equivalent to the SWIR scan rate.

This free white paper describes how SWIR

This free white paper describes how SWIRimaging can improve the efficiency

in food and beverage inspection systems.

More information about the R-B-G-SWIR line scan camera:

For more information about the Sweep+ SW-4010Q-MCL line scan camera: Please visit the product page