JAI has announced the availability of four new 3-CMOS prism color cameras designed for use in microscopy-based systems where maximum control of dust, lint, and other foreign object debris particles (FODs) in the optical path is critical.

The new Apex Series AP-3200T-USB-LSX is a 3.2-megapixel, 38.3 fps camera featuring three prism-mounted Sony IMX265 CMOS imagers. The AP-1600T-USB-LSX is a 1.6-megapixel camera with three IMX273 CMOS imagers and a full-resolution frame rate of 79 fps. Both models feature USB3 Vision interfaces, whose combination of bandwidth and easy plug-and-play compatibility have made it a widely-used choice for microscopy systems.

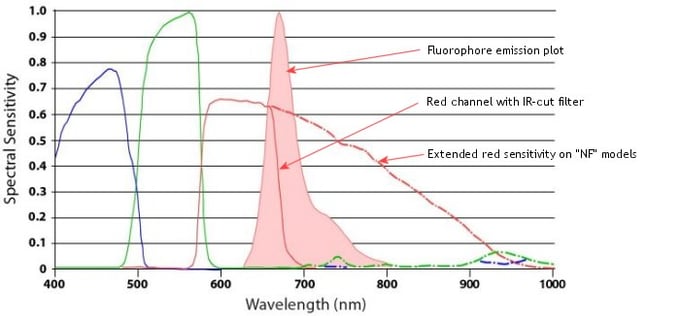

The two additional models (AP-3200T-USB-NF-LSX and AP-1600T-USB-NF-LSX) are configured without standard IR-cut filters for extended red-channel response. System builders can use these models to support life sciences applications where enhanced red sensitivity is required to accentuate specific dyes or stains or to differentiate blood or blood vessels from surrounding tissues. These models are also useful for certain food and industrial applications where both visible and NIR analyses are performed simultaneously.

Spectral response of JAI microscopy cameras with emission plot from a common protein detection fluorophore. Note the amount of the plot that falls beyond the standard IR-cutoff point.

Enhanced screening for dust/FODs

While all of JAI’s microscopy cameras are carefully inspected to ensure exceptional image quality, the new “LSX” models undergo an even more rigorous screening process to ensure they meet even higher standards for dust/FOD suppression. This process is similar to the type of screening used by sensor manufacturers when classifying pixel defects. In addition, the LSX models come with special anti-static dust seals instead of traditional lens caps and feature alumite-treated lens mounts to minimize the creation of FODs when lenses are attached.

White Paper

If you want to learn more about the supreme color image quality provided by JAI's 3-CMOS prism based area scan cameras, you can download the free white paper: How does prism technology help to achieve superior color image quality?

Microscopy software

Like JAI’s previously announced microscopy cameras, the new models offer full integration with two of the most popular microscopy software solutions – Image-Pro® from Media Cybernetics and the µManager open source software package.

Image-Pro is one of the most widely-used microscopy software packages in the world, enabling users and system designers to more easily capture, process, measure, analyze and share microscopy-based images. Custom drivers allow the Apex Series cameras to seamlessly pass images to the Image-Pro software while allowing certain camera functions to be controlled from within the Image-Pro environment.

users and system designers to more easily capture, process, measure, analyze and share microscopy-based images. Custom drivers allow the Apex Series cameras to seamlessly pass images to the Image-Pro software while allowing certain camera functions to be controlled from within the Image-Pro environment.

For those who prefer an open source, non-commercial software solution, the Apex Series  cameras have also been integrated with the µManager (Micro-Manager) software originally created by Vale Lab at the University of California, San Francisco and now being developed and maintained by Open Imaging, Inc. Again, device adapters have been developed to allow the JAI cameras to fully interact with the µManager software. There are no licensing fees for the software, which can be downloaded directly from the micro-manager.org website.

cameras have also been integrated with the µManager (Micro-Manager) software originally created by Vale Lab at the University of California, San Francisco and now being developed and maintained by Open Imaging, Inc. Again, device adapters have been developed to allow the JAI cameras to fully interact with the µManager software. There are no licensing fees for the software, which can be downloaded directly from the micro-manager.org website.

Applications

With their standard C-mount lens mounts, the Apex Series LSX cameras can be easily adapted to most brands of digital microscopes. The 3-CMOS prism technology provides much greater color differentiation than standard Bayer color cameras for brightfield or color fluorescence applications where subtle color differences are critical. The prism design also enables the use of color binning for increased sensitivity when needed, something that typical Bayer cameras do not support. Other unique features versus Bayer cameras include white balancing using shutter times rather than gain to keep image noise at an absolute minimum.

The cameras are designed for a wide range of life sciences applications where extreme color accuracy and spatial precision is required. They can also be used in various industrial applications including wafer inspection and metal inspection systems utilizing color to classify defects; materials science including food, composites, cosmetics, and many other materials; and manufacturing systems that perform particle analysis, spray/spot analysis, or inspection of fibers or other small details.

A few specific application examples:

Live cell imaging - With frame rates of 38 fps or 79 fps the JAI microscopy cameras are very suitable for time-lapse microscopy in live cell imaging and in the general study of cellular dynamics.

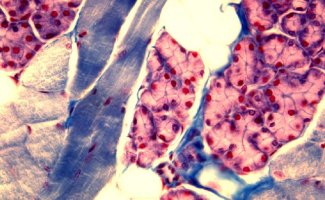

Pathology - Supreme color reproduction, high spatial resolution, and color enhancement tools make the Apex Series cameras ideal for microscopy-based systems used for tissue slice analysis, stain analysis, cell counting, cell classification and other applications in the pathology field.

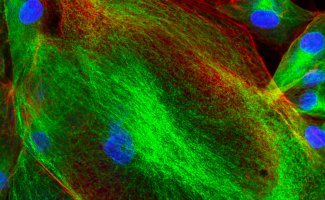

Fluorescence microscopy - Excellent color differentiation, low noise, and extended red sensitivity supports a wide range of fluorescence applications including bacteria counting, disease diagnosis, neuron signaling, and many more.

Materials science - Advanced color systems are needed for analysis of a variety of manufactured materials including coatings, cosmetics, metals, plastics, and composites.

Wafer inspection - Very accurate color image data and high spatial resolution ensure precise error detection and classification of semiconductor defects in advanced wafer inspection systems.