JAI has launched a second version of its Go Series 5-megapixel polarization camera. The new GO-5100MP-PGE is equipped with a standard GigE Vision interface and, just like JAI’s original GO-5100MP-USB with a USB3 Vision interface, the new camera is built around Sony’s IMX250MZR polarized CMOS image sensor.

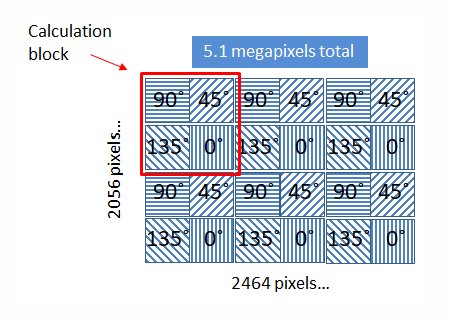

The polarization capabilities are derived from the sensor’s unique 4-way polarized filter array, which consists of four separate polarizing filters – angled at 0°, 45°, 90°, and 135° - that have been arranged in a regular pattern across the sensor. Thus, each block of four pixels can be used as a calculation block to determine the angle and intensity of light reflecting from objects, as well as several other calculations.![]()

The illustration above shows how the Sony IMX250MZR sensor is designed. The polarization capabilities are derived from the sensor’s unique nano wire-grid arrays, which consists of four separate polarizing filters – angled at 0°, 45°, 90°, and 135° - that have been arranged in a regular pattern across the sensor.

![]()

The illustration above shows an example of how a nano wire-grid polarizer works. Due to electric field behavior, all light waves that hit the horizontal wire-grid will be blocked and/or reflected by the grid, except for light waves perpendicular to the alignment of the grid.

The use of polarization filters can not only mitigate reflections and hot spots, particularly when inspecting plastics, glass, and other shiny materials, but can also enable analysis of material thickness, stress points, and other potential defects not detectable using standard machine vision techniques.

An in-camera function uses four-pixel blocks to calculate Angle of Linear Polarization (AoLP) and Degree of Linear Polarization (DoLP) throughout the image.

In addition to being able to provide raw polarization output for all pixels, the camera includes a built-in function for pre-calculating AoLP (angle of linear polarization) – the angle of polarized light striking each 4-pixel block – and DoLP (degree of linear polarization) – which represents the strength of the polarized component relative to the total light falling on the block. By performing these initial calculations in the camera, host resources can be freed up to concentrate on other aspects of the application.

Other camera features include an ROI function, shading compensation, and gamma correction. The main camera body is a compact 29 x 29 x 41.5 mm, with a lens mount supporting standard C-mount lenses. Like other Go Series cameras, it is built to high standards for shock (80G) and vibration (10G) to enable it to perform in industrial environments with an MTBF rating of more than 150,000 hours.

A few application examples:![]()

Internal material stress “frozen-in” during manufacturing of glass and plastics can be problematic. Inspection systems for bottles, eyewear, window glass, etc. can benefit from JAI's GO-5100MP polarization cameras.

![]()

The GO-5100MP polarization cameras can eliminate unwanted glare and reflections from car windshields making it possible to better see inside the cabin for better facial recognition and to provide better evidence in the case of seat belt or mobile phone use violations. ![]()

Scratches, dents and inclusions in finished glass are often easier to detect by analyzing with polarized light. Inspection systems for window glass, bottles, eyewear, and lenses can benefit from the GO-5100MP polarization cameras.

![]()

Polarized imaging can be used to inspect the quality of spray painted surfaces in industries such as automotive and furniture, looking for unwanted scratches, dust spots or uneven paint layers.